RUBYCON’s Game Changer HPB Series

New High-Voltage PMLCAP with Many Advantages

RUBYCON presents a new high-voltage PMLCAP. The HBP series replaces DC-link film capacitors, is up to 45% smaller and offers many advantages such as higher heat resistance, miniaturisation and no short circuit risk. Specifications include 500V-900V and 5µF-25µF, used as DC link capacitors in applications such as motor drive compressors, OBCs and DC/DC converters.

Fact-Overview:

- PMLCAP stands for Polymer Multi-Layer CAPacitor

- No piezoelectric effect causing noise

- No DC bias derating

- Stable capacitance in wide temperature range

- No risk of short circuit, smoke or fire

- Used in high-end audio applications as a replacement for MLCCs

- Can be used as a snubber capacitor to replace film capacitors in a smaller format

- Over 300 million units have been shipped into the market.

- Widely used, including in the automotive industry and even in NASA's Mars lander "InSight".

The HPB series offers two major advantages compared to film capacitors:

- Higher heat resistance, i.e. the ability to withstand 125°C and more.

- Miniaturisation, reaching almost half the volume of film capacitors on the market

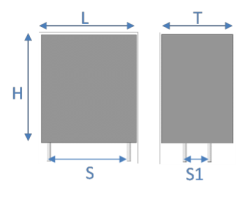

This table shows the specification lineup that is currently considered.

SPECIFICATIONSFor a 900V product with 20µF, even with a voltage gradient of 250V/µm, the HPB series can reduce the component volume by up to 30% compared to today's standard 125°C film capacitors (Volume 56.7cm³ --> 40.1cm³).

RUBYCON continues to focus on increasing the voltage gradient. The next goal is to reach 300V/µm. This would mean that the volume can be reduced by up to 45% in the case of a 900V product with 20µF (Volume 56.7cm³ --> 31.5cm³). Despite this miniaturisation advantage, the HPB series can easily withstand 125°C.

Series samples of the HPB series are expected to be available from autumn 2023. With this HPB series, RUBYCON offers a reliable solution for high-voltage applications that enables smaller, heat-resistant components without compromising performance. This advancement is in line with the increasing demand for more functional components in the evolving automotive market and beyond.

Your Contact Person

For more information, please contact Yasunobu Ikuno.